0086-315-6135333

0086-315-6193333

©2018 Tangshan Hengfeng Machinery Manufacture Co.,Ltd All Rights Reserved.Powered by www.300.cn

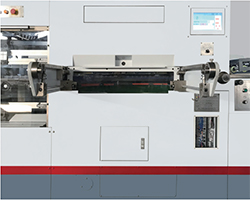

HF-1060/800MF

The HF-1060MF Automatic Die-cutting and Stripping Machine with stripping station is the pivotal equipment which is designed for die cutting, creasing and cold embossing paper products such as paper cassettes, box board containers, paper trademarks, etc.Unique driving gear adopt high-precision indexing mechanism, pneumatic lock up, pneumatic clutch, overload protection, electric compression relief, etc. to ensure a stable and high speed running.

This machine is equipped with practical and reliable mechanisms such as pre-stack device, secondary feeding device, variable speed paper feeding mechanism, automatic secondary delivery mechanism, pneumatic sampling, automatic timing lubricating device, cooling facility for oil, etc., which ensure the excellent performance of the machine.Well-known brand electrical components and driving elements are adopted to ensure die-cutting precision and reliability of running. PLC and electronic cam monitor cooperate to control the whole machine. It is convenient for fault diagnosis. Human-machine interface monitors machine state displaying running instructions, trouble location, trouble shooting to fully actualize human-machine communication. Industry refrigerator for electrical cabinet ensure that electric components work stably in a uniform temperature.

Technical Parameters

|

Model |

HF-1060MF |

Max.Die-cutting Speed |

7500 |

|

Cutting Mode&Function |

Die cutting and stripping |

Max.Height Feeding Pile |

1630 |

|

Max.Sheet Size |

1070*790 |

Max.Height Delivery Pile |

1350 |

|

Min.Sheet Size |

450*360 |

Precision |

±0.1 |

|

Min.Front Margin |

5mm |

Heating Zone |

_ |

|

Max.Die-cutting Size |

1060*780mm |

Main Motor Power |

11 |

|

Max.Die-cutting Pressure |

300 |

Total Power |

43 |

|

Sheet Specifcation |

100~2000 |

Net Weight |

19.5 |

|

Corrugated paper |

≤4.5 |

Overall Dimension |

7337*4043*2311 |

Standard configuration and functionality

|

1.FEEDING UNIT High precision feeding head which can smoothly running with thin paper and all kinds of cardboard in high speed.Equipped with gantry type preloading mechanism.Main and vice feeding platform working by turns to achieve non-stop running. |

|

|

2.CONVEYING UNIT Vacuum conveying system which can ensure thin paper stable and precise conveying. Equipped with Taiwan push-and-pull dual purpose guide lay to make stable positioning in high speed running;conveying wheel quick-adjusting mechanism which can ensure high working efficiency. |

|

|

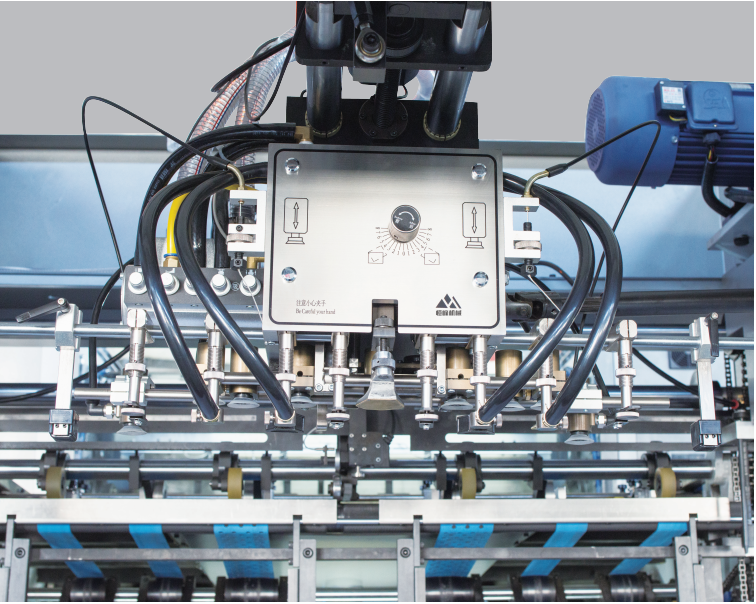

3.DIE CUTTING STEEL PLATE FINE-ADJUSTING DEVICE Steel plate fine adjusting device which can revise the bottom die quickly.improving working efficiency greatly. |

|

|

4.LONGIUDINAL HIGH POINT FOIL FEEDING UNIT Longitudinal three shafts high point foil feeding system and extension type foil release frame can make quick and convenient foil changing,transverse two shafts servo control foil feeding system,disrupted foil checking system. |

|

|

5.LONGITUDINAL FOIL DELIVERY UNIT External longitudinal hair roller foil delivery system is convenient for waste recovery and recycle. |

|

|

6.DELIVERY UNIT Delivery unit adopts hair brush and back sucking system to make tidy paper stack;Electric vice delivery device can achieve non-stop running;pneumatic sampling function. Label mark counting function is optional. |

|

Intelligent arithmetic system can make automatic calculation of leapfrog project for different products,which can save foil greatly. |

|